Tool Room Services

Why Total Metal Products?

One of our key business objectives is to keep our toolroom assets up to date with the latest technologies. For over 10 years TMP has invested heavily into our toolroom.

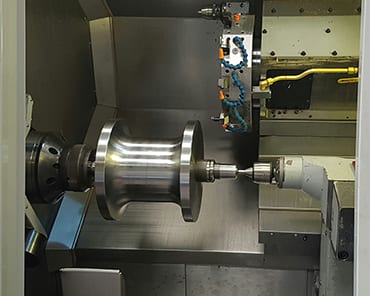

Variety of CNC Machines

Our current toolroom consists of the following CNC machines, which are all fitted with Renishaw tool and spindle probes:

- Haas UMC 750 - full simultaneous 5-Axis CNC machining centre

- Mazak QT250MY - CNC turning centre with live tooling turning / milling

- Haas VM-3 – high-performance VMC with 4-Axis

- Haas VF-9/40 – large capacity VMC with 4-Axis

- Haas VF-4SS - high-performance Super-Speed VMC

- Haas VF-4 – 3-Axis VMC

We have a continual commitment to invest in our toolroom assets, as well as expanding our qualified and experienced tool makers and promoting our apprenticeship program.

TMP offers a full-service manufacturing process for parts and components. We can also provide a variety of general toolroom services, including milling, turning, grinding, polishing, drilling and reaming. Some of the many manufacturing solutions and processes that we provide. We can produce any type of machined item from basic plate work, through to medium volume batch work.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What are Toolroom Services?

With manufacturers deciding to concentrate on their core business their non-core toolroom services are outsourced to precision engineering companies such as TMP.

TMP are able to provide you with an economical solution for your manufacturing requirements, especially as TMP are able to provide numerous operations / services in-house, when, traditionally these would have had to be sent to separate vendors.

TMP acts as your outsourced toolroom, working closely with your production control and quality teams providing you with an extension to your operation and added flexibility to your production environment.

TMP can produce a broad range of toolmaking solutions.

We have extensive experience in:

- Stretch Forming

- Stretch Bending

- Roll Forming

- Welding Jigs

- Assembly Jigs

- Metal Punching

- Sheet Metal Piercing

- Toolmaking Design

- Toolmaking

- Tool Room Services

- Contract Manufacture

Supporting the world’s biggest brands

New Capabilities

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management