Assembly Jigs

Why Total Metal Products?

For over 10 years Total Metal Products (TMP) has been designing, producing, servicing and installing assembly jigs and assembly fixtures / production fixtures.

Assembly Jigs and Fixtures

Each of our assembly jig and assembly fixture / production fixture solutions is designed ergonomically to ensure the workplace fits the needs of the worker, rather than the worker having to adjust to the workplace.

TMP designs, delivers and supports a comprehensive range of assembly jig and assembly fixture solutions, via our in-house jig and fixture design facility. Our assembly jigs and fixtures can be operated manually or designed to integrate with automated production solutions. TMP has extensive knowledge of, and experience in, providing robotic automation production solutions.

Our assembly jigs and assembly fixtures can incorporate Poka Yoke techniques, which are an important requirement within the automotive industry, eliminating the possibility of producing incorrect parts.

TMP are able to supply and integrate into your assembly production lines workpiece positioners like turn-tilt modular tables for both manual and robotic assembly operations. With a comprehensive range of designs and solutions we can accommodate workpieces across a broad range of weights and sizes. For heavier / larger requirements we can provide systems which can be adjusted hydraulically.

Prototype Solutions

Our assembly jigs and fixtures are designed, manufactured and assembled in-house.

Our experienced team of designers, project management and production engineers work in collaboration to produce the most effective assembly jigs and fixtures to your specification and business requirements. We always deliver our solutions on time and on budget.

TMP can also design and manufacture the technology which sits either side of assembly jigs and assembly fixtures providing a fully automatic assembly process with automated testing equipment. Our experience across a wide range of technologies allows us to provide you with the optimum solution for your production requirements.

We design our assembly jigs and production fixtures to minimise production errors due to misalignment, material over stressing, breakage etc, as well as prepare the component(s) under construction for the next stage. Misalignment or over stressing causes problems in production and post production with an increased level of production rejection, increased warranty claims / customer rejection, poor quality and an increased financial cost to the business.

We produce a comprehensive range of innovative assembly jigs and assembly fixtures / production fixtures which improves the consistency and quality of your finished product, with a reduced time to produce, which directly reduces your direct and indirect costs, at the same time improving the occupational welfare of your workforce.

If your business has a requirement for prototype, low volume or end-of-life manufacturing we provide solutions to these challenges via our group partner company TMP Manufacturing.

TMP Manufacturing is able to produce your low volume requirements, with production to schedule, management of your raw material supply chain, finished product storage and onward delivery to your customer.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What is an Assembly Jig?

An assembly jig is a device which keeps the workpiece stable to enable it to be assembled, measured or checked accurately and repeatably.

Holding the workpiece at specific points or allowing workpieces to be clamped together, jigs allow production processes such as drilling, tapping, gluing, material removal etc, or production verification process like measuring, “Go / No go” checking etc, to be carried out effectively and consistently.

The assembly jig is a production device which holds, supports and locates the workpiece in order to guide one or more tools or process operations.

The primary purpose of an assembly jig is to provide the production manufacturing process with a repeatable, accurate and consistent platform.

Assembly jigs are designed to support both unidimensional machining or bi-directional processing. They can be further designed to integrate into an automated or semi-automated production cell or workflow.

Assembly fixtures / production fixtures (fixtures) are the workpiece holding devices which grip, support and locate the workpieces under production. Fixtures also hold a workpiece or finished product in place for optical / laser scanning to check manufacturing quality.

The main purpose of an assembly fixture / production fixture is to hold and secure the workpiece to prevent movement during the assembly or production process; and / or provide accurate and repeatable alignment for machining operations.

Assembly jigs and assembly fixtures / production fixtures maximise production efficiency and productivity as well as the occupational welfare of your production workforce.

They are key; improving reliability, accuracy and quality of the manufacturing production process as well as optimising production cycle times.

There are distinct differences between the intended functions of assembly jigs and assembly fixtures / production fixtures (fixtures). As well as holding and locating the workpiece assembly jigs guide tools e.g., cnc late / mill, whereas, fixtures limit their functionality to holding and locating the workpiece.

Assembly jigs and assembly fixtures / production fixtures reduce the complexity of manufacturing processes, make the assembly process more precise, and reduce the production hassle for the production workforce. They can also be used to make production a less skilled process, increase machine productivity, improve production quality and maximise workforce effectiveness, all key factors in reducing production costs.

TMP can produce a broad range of toolmaking solutions.

We have extensive experience in:

- Stretch Forming

- Stretch Bending

- Roll Forming

- Welding Jigs

- Metal Punching

- Sheet Metal Piercing

- Toolmaking Design

- Toolmaking

- Tool Room Services

- Contract Manufacture

Supporting the world’s biggest brands

New Capabilities

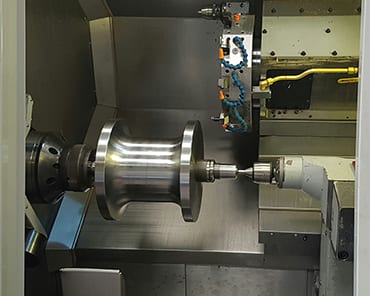

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management