Stretch Bending

Why Total Metal Products?

As a sector leading machine design and tool making company Total Metal Products (TMP) supplies high quality stretch bending tooling systems and has the in-house capability to design, manufacture, commission and service your stretch bending requirements.

Stretch Bending Solutions

TMP’s stretch bending solutions can be operated standalone or they can be seamlessly integrated into your manufacturing process operations. Our industry specific in-house design, project management and production teams work together to provide you with a stretch bending solution which perfectly meets your specification and your business requirements. Our solutions are delivered on time and on budget.

We have a variety of standard machine designs which can be adapted to meet the needs of your business. If required we are also able to provide you with fully bespoke solutions.

Fitted with CNC servo axis motion controllers our industry leading stretch bending solutions ensure consistent accuracy and fully repeatable control of your stretch bending process. An added benefit of our design is that our solutions are quicker to tune to the desired shape and can have different stretch profiles for different materials i.e., aluminium extrusions which may vary in age hardness.

We can also provide auto loading systems for your high output projects, directly linked to the roll form lines. Automatic unload systems can also be designed and supplied which, when combined with automatic loading, will significantly reduce manning requirements and optimise end-to-end processing time.

Prototype Solutions

TMP’s solutions produces components which have a greater level of quality and complexity, and where required, utilise new material technologies.

They are designed to reduce production cycle times and reduce waste material and process time, factors which increase your process efficiency and improve your cost effectiveness.

TMP can also provide you with a solution for any prototype, low volume or end-of-life stretch bending manufacturing requirements you may have via TMP Manufacturing, our group partner company.

TMP Manufacturing can support your low volume requirements, with production to schedule, management of your raw material supply chain, secure / bonded storage of your finished product and delivery to your customer utilising your paperwork and systems where necessary.

If you have any questions about our stretch bending solutions, or wish to explore your manufacturing services requirements, please contact us.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What is Stretch Bending?

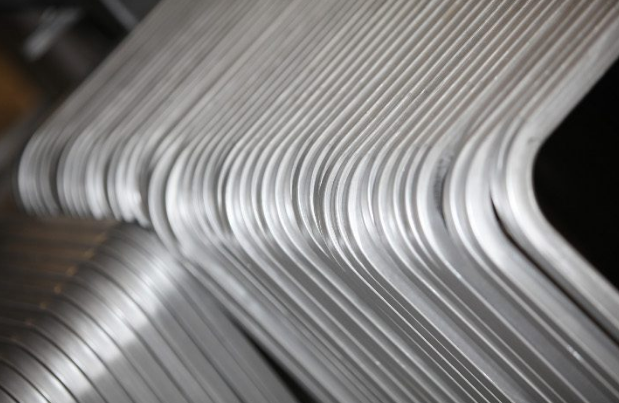

Stretch bending is where the raw material / blank is bent or “stretched” to create parts with the desired shape.

These parts are often stronger as well as lighter, as a result of using strong materials and working with higher quality machines. As the blank processes through the machine, it strengthens the metal, helping it retain the shape required.

Stretch bending technology is suitable for tubes and (extruded) profiles in aluminium, steel and stainless steel.

To create curvature, the extruded section is wrapped around a die. Some over bending is usually required as the extrusion is likely to exhibit a degree of spring back.

Bending Extrusion Methods

Ram / Push Bending

In this method a semi-circular ram is pushed against the blank. To either side pressure dies support the section, pivoting as it wraps around the ram. The ram is shaped as a mirror image of the external section profile, as are the pressure dies. Multiple bends can be placed close together although only one is made at a time. The tightest achievable bend radius is around four times the diameter of the section.

Three-Roller Bending

As with ram / push bending, the section is supported in two locations while a die pushes down in between. The rollers replace the ram and pressure dies. Shaped to match the section, these rotate, pulling the section through and creating a large radius.

Rotary Draw Bending

This method can produce very tight bend radii – around the same as the section diameter. The bending die is circular with a mirror of the section external profile over some 270° of surface. The blank is clamped against this die and held in place by a pressure die. The bending die rotates, wrapping the section around it. Precise bend angles are achievable by controlling the die rotation.

Compression Bending

In this method the blank is clamped against the side of a stationary ram which has the mirror profile around a 180° arc. A compression die then wraps the blank around the ram. Minimum radius is around three times the diameter of the blank. Compression bending is often performed on twin head machines to produce forms with symmetrical bends at either end.

TMP can produce a broad range of toolmaking solutions. We have extensive experience in:

- Stretch Forming

- Roll Forming

- Welding Jigs

- Assembly Jigs

- Metal Punching

- Sheet Metal Piercing

- Toolmaking Design

- Toolmaking

- Tool Room Services

- Contract Manufacture

Supporting the world’s biggest brands

New Capabilities

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management