Toolmaking Design

Why Total Metal Products?

As a sector leading machine design and tool making company Total Metal Products (TMP) supplies high quality stretch bending tooling systems and has the in-house capability to design, manufacture, commission and service your stretch bending requirements.

Industry Leading Toolmaker

Our designers make full use of the industry leading CAD - Autodesk Inventor, CAM – Mastercam, FEA - Autodesk Inventor and Document Control - Autodesk Vault software packages.

Complete CAD design, 3D modelling and development capabilities, along with full compatibility with industry design and engineering data (CATIA, Unigraphics, AutoCad), make TMP your first source for the solutions you need.

Total Metal Products (TMP) has been developing its design team and capabilities for over 10 years. As well as design, TMP, an industry leading toolmaker, have been producing, servicing and installing production and production line solutions.

Our dedicated in-house design team work collaboratively with our project management and production engineers to provide you with the optimum design solution, which meets your specification and the requirements of your business.

With a full complement of qualified and experienced tool makers and an on-going apprenticeship program, TMP can design and build all forming and bending tools, metal punching / piercing and jigs "in-house"; this unique capability reduces lead times and delivers your project, on time, and on budget.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What is Toolmaking Design?

Tooling design is defined as “…. a specialized area of manufacturing engineering which comprises the analysis, planning, design, construction and application of tools, methods and procedures necessary to increase manufacturing productivity.” [Dr. Nageswara Rao Posinasetti]

Designers ensure that the tools they design:

- Produce the workpieces / end products at the lowest practical cost

- Has the highest production rates

- Produce the workpiece / end product with a consistent level of quality

- Are safe and easy to operate

TMP’s design team can provide you with a design only solution; however, we believe one of the real benefits of working with TMP is the ability to provide the customer with a full end-to-end service including design, tool manufacture, prototype / pre-production run off and if required installation and commissioning. This integrated approach allows for much smoother and cost reduced on the fly” changes to be made, project scope creep or workpiece design modification.

Supporting the world’s biggest brands

New Capabilities

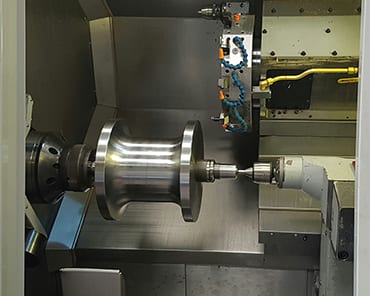

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management