Stretch Forming

Why Total Metal Products?

Total Metal Products (TMP) are a sector leading machine design and tool making company which designs, manufactures, commissions and services high quality stretch forming tooling systems.

Stretch Forming Techniques

Our stretch forming solutions are designed to operate standalone or integrate seamlessly into your manufacturing process operations.

TMP’s dedicated in-house design team, project management and production engineers work collaboratively to provide you with the optimum stretch forming solution, which meets your specification and the requirements of your business; on time and on budget.

TMP recognises that stretch forming techniques and materials are constantly evolving. Our knowledgeable, experienced and industry aware team are continually adapting our designs to provide innovative solutions to meet these challenges.

Our leading-edge modern stretch forming solutions utilise CNC servo axis motion controllers to ensure accurate / repeatable control of the process; this has the added benefit of being quicker to tune to the desired shape and potentially have different stretch profiles for varying materials i.e., aluminium extrusions which may vary in age hardness.

Our solutions produce components with a greater level of quality and complexity, utilising new material technologies, reducing cycle time and waste, which increases your process efficiency and cost effectiveness.

Stretch Forming Manufacturing

TMP also provides a solution for your prototype, low volume or end-of-life stretch forming manufacturing requirements via our group partner company TMP Manufacturing.

TMP Manufacturing are able to provide for your low volume requirements, production to schedule, management of your raw material supply chain, finished product storage and onward delivery to your customer.

TMP Services

TMP provides the following range of services and solutions.

If you have questions or require further information, please do not hesitate to contact us.

What is Stretch Forming?

When a material is simultaneously stretched and bent to produce a curved form this is what is referred to as “Stretch Forming”.

The raw material or blank, which can be metal sheet, rolled section or extrusion, is bent around a former, known as a form die or tool, which forms the required component whether it has a single or multiple curved radii.

The section is gripped at either end and then bent around the former with stretch controlled with either mechanical cams or servo-controlled axis.

Stretch Forming produces a final part with better shape control and an improved surface quality, which does not require additional finishing or polishing and which is perfectly curved, is produced with reduced cost and less waste.

Stretch Forming is used across many industries including automotive, transportation, and architectural.

TMP can produce a broad range of toolmaking solutions.

We have extensive experience in:

- Stretch Bending

- Roll Forming

- Welding Jigs

- Assembly Jigs

- Metal Punching

- Sheet Metal Piercing

- Toolmaking Design

- Toolmaking

- Tool Room Services

- Contract Manufacture

Supporting the world’s biggest brands

New Capabilities

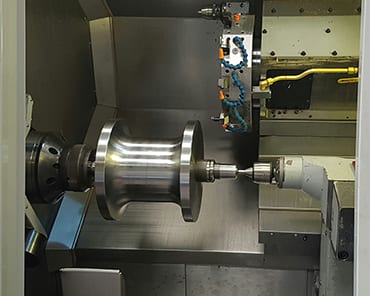

TMP expands our CNC High Speed milling and turning capacity with the addition of a Haas UMC 750 5-Axis and Mazak QT250MY turning centre. Further investment in our toolroom, build room and design centre are planned for 2023.

The Future at TMP

At TMP we continually reinvest in the business. TMP launches operations in North America and Turkey. TMP reduces its environmental impact by installing a 66 kWp solar farm.

Accreditations

Implementing a suite of internationally recognised accreditations in Quality, Environmental and Occupational Health & Safety management, demonstrates our commitment to continually improve our working methods and working environment.

Let us know about your requirements

Introducing

TMP Manufacturing

Specialising in prototype, low volume, end-of-life component manufacture and supply chain management